Two main steps of processing granular organic fertilizer

The processing of granular organic fertilizer mainly requires two steps, which are the pre-fermentation treatment part and the deep processing granulation part.

Fermentation treatment part

After the compost raw materials are transported to the storage yard, the moisture content and carbon-nitrogen ratio of the compost are roughly adjusted according to the composition of the raw materials through a mixing device. After mixing the mixed raw materials into a fermentation pile, you should supply oxygen and turn the pile to perform aerobic fermentation.

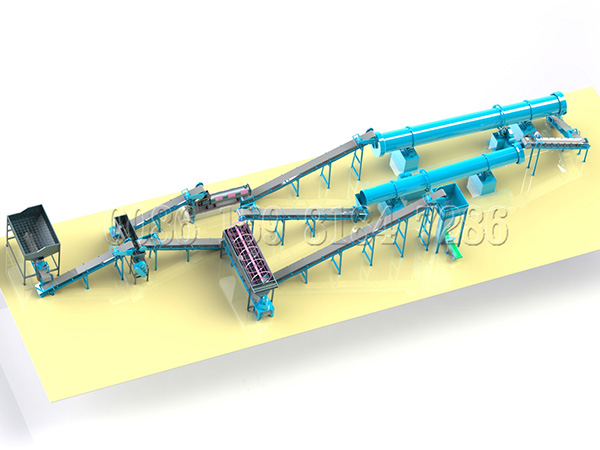

Granulation processing part

After the fermentation, the materials are crushed and screened. After the undersize is granulated, it is sent to the dryer and then cooler. Finally, they are packaged and sorted into the warehouse. The unqualified oversize is returned to the crushing process for reuse.

The entire organic fertilizer production process specifically includes physical dehydration → mixing (proportional mixing of bacterial species + fresh animal manure + crushed crop straw) → fermentation → crushing → granulation → drying → cooling → sieving → finished product → packing→warehousing.