What is the investment in an organic fertilizer plant with an annual capacity of 350,000 tons?

The organic fertilizer plant with an annual output of 350,000 tons requires organic fertilizer production line, raw materials, water, electricity and employee and so on.

First of all, what are the steps of the organic fertilizer production?

1. Production process

1) Pile type fermentation needs ground compost turner or groove type needs groove type compost turner.

2) Sprinkling the microbial inoculum evenly and turning the pile to reach the high temperature, deodorizing, decomposing and killing the weeds

3) The times of fermentation is 7-12 days. And the number of turnings according to the local temperature.

4) When the raw materials are completely fermented and decomposed, they can be sent to rotary drum screening machine. And the powdery fertilizer that has been screened can be sold directly.

5) The selected large pieces are crushed with a crusher.

6) Mixing the required trace elements with a mixer

7) Granulating the mixed powdery materials with a granulator

8) Sending the pellets to the dryer and cooler

9) The final pellets are packaged by automatic packaging machine for selling.

2.Facilities

There are finished product stacking warehouse, semi-finished product warehouse, raw material warehouse, employee office plant or fermentation tank ( 6 meters wide × 50 meters long × 7 bars ). It depends on the local construction budget. And the ground compost turner does not need to build grooves.

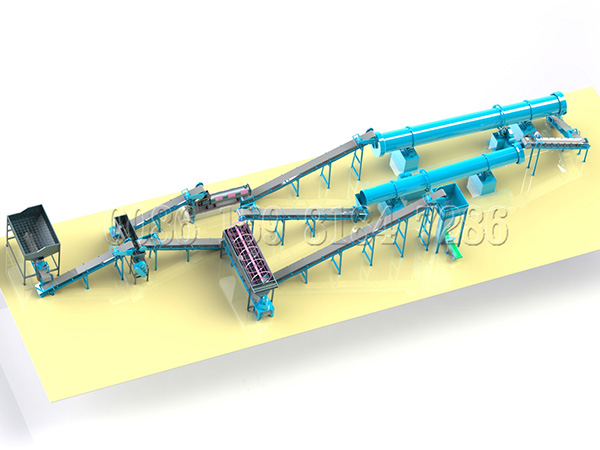

3.Equipment

The organic fertilizer production line mainly includes compost turner, rotary drum screening machine, crusher, mixer, granulator, dryer, cooler, packing machines and belt conveyor. And the length and number of belt conveyors can be designed and laid out according to the actual site conditions.