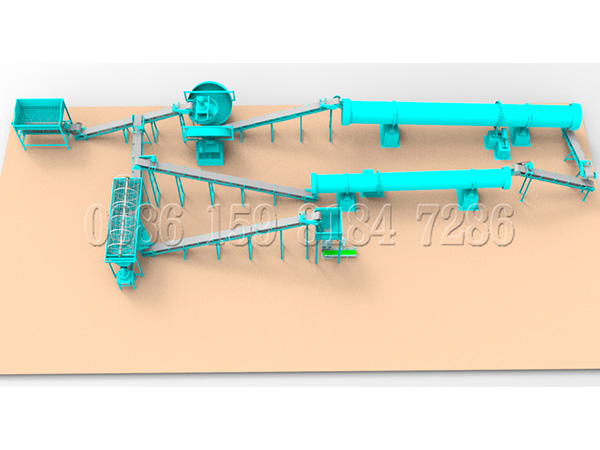

The work flow of the pig manure disc granulator organic fertilizer production line

1. The fermented pig manure is transported directly to the raw material mixer

2. The mixed pig manure is transported to the disc granulator.

3. The granules are transported to the organic fertilizer dryer for heat exchange with the heat from the hot blast stove.

4. It is transported to the screening machine to sort particles, and the fine particles are directly returned to the disc granulator to continue to participate in the adhesion of the particles into balls.

5. The hot granules are transported to the organic fertilizer cooler. It can cool the fertilizer through natural cold air or strong cold air.

6. The cooled granules are transported to the finished product screening machine. The large particles are crushed by the pulverizer and then returned to the disc granulator to continue to participate in ball formation.

7. The qualified products after screening are transported to the coating machine for coating.

8. Finally, the coated granules are transport to a fully automatic packaging scale for weighing, packaging and storage.

The pig manure disc granulator organic fertilizer production line includes fermentation equipment, pulverizer, mixer, disc granulator, dryer, cooler, screening machine, packaging machine, etc. We have many types of equipment for manufacturing fertilizers, and different organic fertilizer processing equipment plans need to be formulated according to the different materials and capacity. Welcome to contact us for specific information.