What equipment is needed to make organic fertilizer from sludge?

What equipment is needed to make organic fertilizer from sludge? How much is the sludge organic fertilizer production equipment?

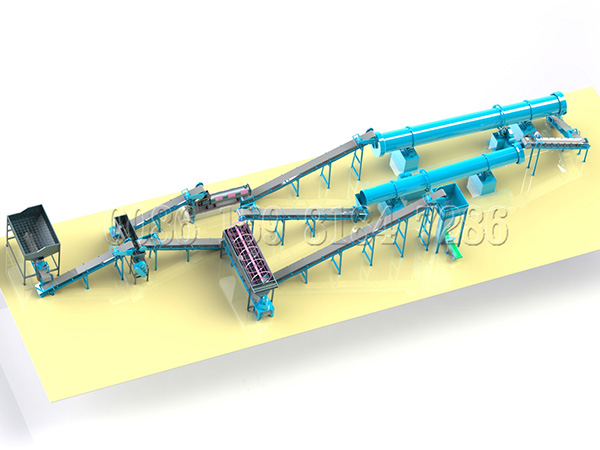

The production of organic fertilizer from sludge mainly uses fermentation equipment, mixer, disc granulator, dryer, cooler, screening machine and packing machine and so on. The sludge organic fertilizer has obvious social and economic benefits.

The living sludge is produced by the treatment of domestic sewage. The domestic sewage is produced in the toilets, kitchens and bathrooms of the residents. Therefore, the living sludge is “nutrient-rich” and the organic matter content is generally as high as 50%. Above, the index of nutrients such as nitrogen, phosphorus and potassium is between 5% and 7%. And the content of heavy metals is very low, which meets the basic standards of organic fertilizers.

The production of organic fertilizer from sludge mainly uses BM sludge biological fermentation bacteria and organic or inorganic materials such as oil residue, plant straw and so on. After high temperature fermentation for about 12 days, the pathogenic microorganisms and roundworm eggs in the sludge can be killed effectively.

The organic fertilizer production line generally includes: raw material selection (chicken manure, straw, sludge, grass charcoal, etc.) → fermentation treatment → ingredient mixing → granulation → cooling and screening → sealing → finished product storage. Welcome to contact us for more information.